Introduction

In the ever-evolving landscape of electronics production, the want for trustworthy and effective bonding programs has by no means been greater principal. The twine bonding activity, an fundamental thing in semiconductor packaging, has considered huge improvements over the years. Among these strategies is thermosonic wedge bonding—a technique that combines thermal and ultrasonic vigour to create stable bonds among wires and substrates. This article delves into the ins and outs of thermosonic wedge bonding, exploring its mechanics, blessings, programs, and far extra.

What is Wire Bonding?

Wire bonding is a pivotal task in electronics manufacturing that connects the die of a semiconductor to its package deal or substrate simply by nice wires. It is vital to numerous industries, together with telecommunications, automotive electronics, consumer units, and scientific appliance.

How Wire Bonding Works

The cord bonding way entails several steps:

Preparation: The surfaces are cleaned to dispose of contamination. Positioning: The die is accurately placed at the package. Bonding: A wire is attached to the die due to a bonding software. Sealing: The connection is executed with warmness or ultrasonic vigor.Types of Wire Bonding Techniques

- Ball Bonding: Typically used for gold wire; it creates a small ball on the conclusion of the wire in the past making contact with the pad. Wedge Bonding: Utilizes a flat tool to press towards the cord devoid of forming a ball. Ribbon Bonding: Involves wider wires that can attach assorted pads simultaneously.

Applications of Wire Bonding

Wire bonding reveals functions throughout severa sectors:

- Semiconductor devices LEDs MEMS (Micro-Electro-Mechanical Systems) Power modules

Understanding Thermosonic Wedge Bonding

Thermosonic wedge bonding represents an advanced style of cord bonding that enhances bond capability even though keeping up reliability.

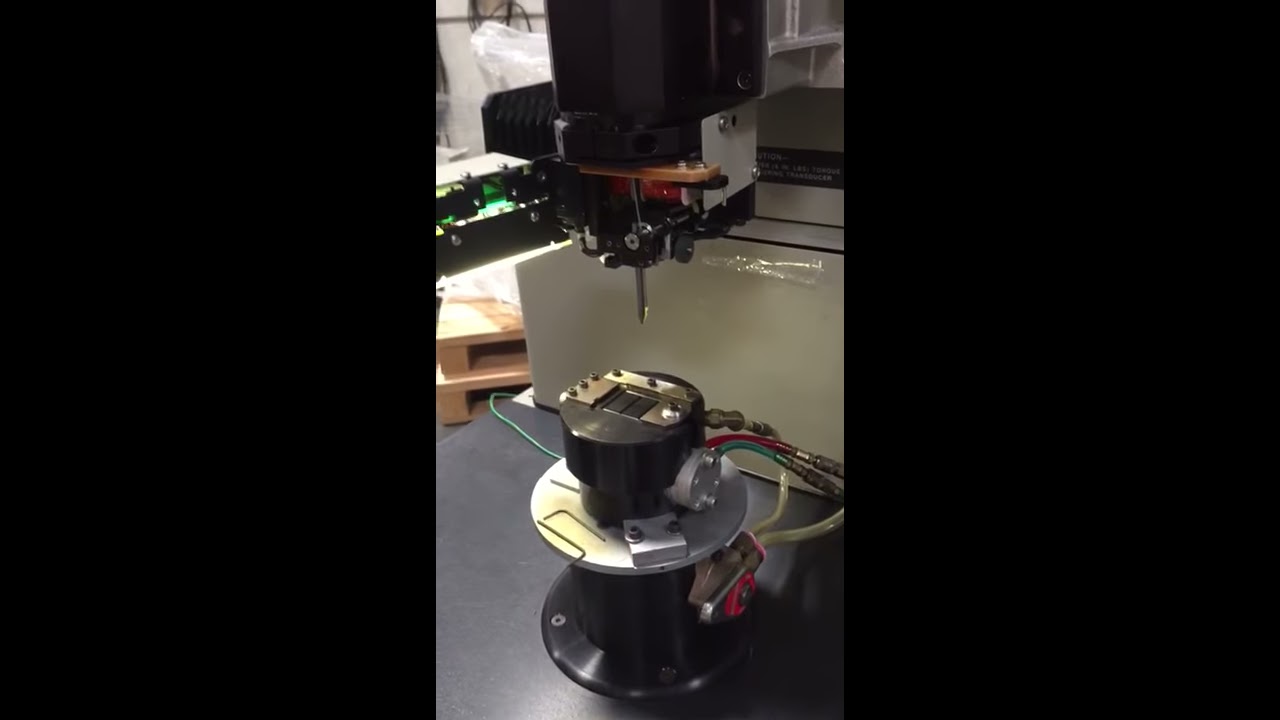

The Mechanics Behind Thermosonic Wedge Bonding

This process integrates equally warm and ultrasonic electricity throughout the bonding approach:

Heat Generation: The thermosonic bonder applies localized warmness to soften the ingredients being bonded. Ultrasonic Energy: Simultaneously, ultrasonic vibrations wreck down any oxide layers at the floor and facilitate intermetallic formation.Advantages of Thermosonic Wedge Bonding

- Improved Reliability: Ensures potent connections by means of cutting bond failures. Versatility: Suitable for diversified components like gold, aluminum, copper, and silver. Cost Efficiency: Reduces fabric waste with the aid of greater bonding precision.

Leveraging Thermosonic Wedge Bonding for Improved Bonds

When brands seek tactics to reinforce their manufacturing approaches, leveraging thermosonic wedge bonding proves important. By utilising this technology, they are able to reap larger bond first-rate even as minimizing quotes linked to remodel or replacements.

Key Considerations for Implementation

Implementing thermosonic wedge bonding requires careful attention of a few factors:

Material Selection: Choose fabulous constituents dependent on conductivity and thermal homes. Equipment Calibration: Ensure that the thermosonic wire bonder settings are optimized for categorical duties. Environmental Controls: Maintain cleanroom stipulations to circumvent illness all the way through construction.Comparative Analysis: Wedge vs Ball Bonding Techniques

Many ask how thermosonic wedge bonding compares with usual ball bonding ways.

| Aspect | Wedge Bonding | Ball Bonding | |----------------------|---------------------------------------|---------------------------------------| | Equipment Cost | Generally shrink | Higher thanks to additional tooling | | Material Flexibility | Compatible with different elements | Primarily acceptable for gold wires | | Process Speed | Faster in top-quantity purposes | Slower with the aid of ball formation | | Reliability | Superior beneath tension | Good however varies with fabric |

Wedge Bonding Applications in Semiconductors

Thermosonic wedge bonding has found out its vicinity inside semiconductor fabrication strategies wherein reliability is paramount.

Use Cases in Semiconductor Packaging

High-frequency RF modules require specific connections which could withstand environmental stressors. Power electronics most commonly make use of this technique attributable to its capacity to address increased latest plenty devoid of degradation.Understanding Wire Bond Failure Analysis

Despite advancements in know-how like thermosonic wedge bonding, disasters might nonetheless take place.

Common Wire Bond Failure Modes

- Bond Lifting: Occurs whilst inadequate pressure or temperature is implemented at some point of bonding. Heel Cracking: A fracture at the bond interface simply by thermal rigidity.

Failure Analysis Procedures

Visual Inspection X-ray Imaging Pull/shear testsFAQs about Thermosonic Wedge Bonding

1. What elements are fabulous applicable for thermosonic wedge bonding?

Thermosonic wedge bonding works properly with gold, aluminum, copper, and silver wires on account of their conductive properties and compatibility with ultrasonic vitality.

2. How does thermosonic wedge bonding recover reliability?

By combining warm and ultrasonic strength throughout the time of the procedure, it produces superior bonds at the same time reducing failure premiums related to oxide layers on surfaces.

3. Is thermosonic wedge bonding value-helpful?

Yes! While initial system expenditures is probably bigger than widely used equipment, lengthy-term rate reductions come from reduced transform rates and better yield.

four. Can thermosonic wedge bonds be used in high-frequency packages?

Absolutely! They are peculiarly triumphant in RF modules the place sign integrity is significant caused by their low resistance connections.

five. What are commonplace considerations encountered throughout cord bonding?

Common problems encompass incomplete bonds caused by insufficient drive settings or infection on surfaces most effective to negative adhesion satisfactory.

6. Are there exercise packages available for learning wire bonding suggestions?

Yes! Many au ball wire bonding enterprise organizations be offering courses ranging from amateur tutorials on wire bonding basics up by developed processes comparable to thermosonic wedge bonds.

Conclusion

In conclusion, leveraging thermosonic wedge bonding represents a big development in attaining more suitable bonds inside of electronic devices and semiconductor packaging procedures. Its distinct mix of thermal management coupled with ultrasonic strength now not most effective enhances bond reliability yet also presents versatility across a couple of constituents used this present day in technology manufacturing practices around the globe!

As brands keep adapting their approaches in the direction of better performance although making certain advantageous outputs—thermosonic wedge-bonded connections will absolutely play an increasingly needed function moving ahead!

This finished help serves as a foundational aid good-desirable for engineers trying insights into modern practices surrounding progressed methodologies like Leveraging Thermosonic Wedge Bonding for Improved Bonds!